Characteristics of Magnetite

Magnetite is one of the most common and widely used iron ores. Because of its strong magnetism, it can be efficiently recovered through weak magnetic separation. This property makes magnetite a key raw material in the steel industry and plays a vital role in metallurgy, building materials, and other sectors.

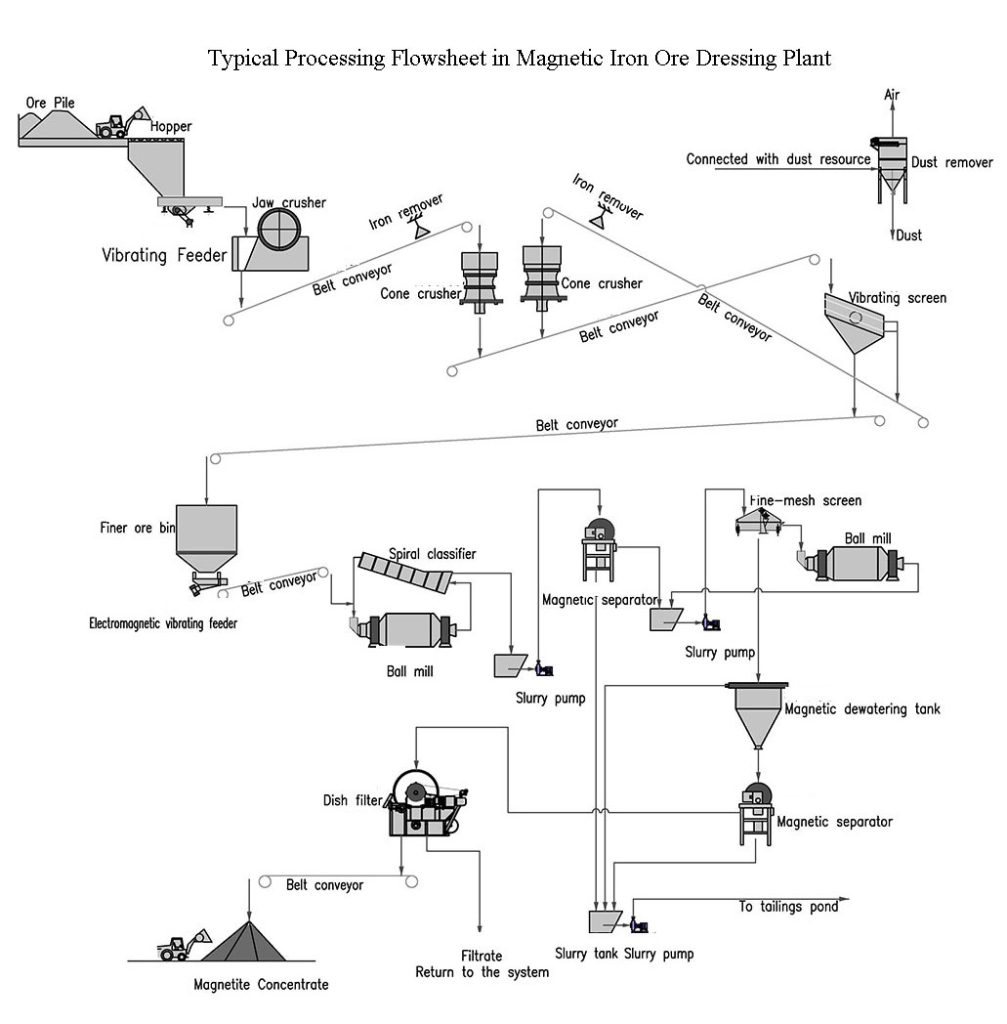

Selection of Magnetic Separation Process

The process of magnetic separation varies depending on particle size:

- When the ore grain size is above 0.2-0.3mm, one-stage magnetic separation is usually sufficient to obtain high-grade concentrates.

- When the grain size is below 0.2-0.3mm, two-stage magnetic separation is required to ensure both concentrate grade and recovery.

Phased Magnetic Separation and Dry Pre-selection

In certain cases, if coarse grinding is sufficient to separate tailings from qualified concentrates, the phased magnetic separation method can be adopted. This approach reduces energy consumption, increases efficiency, and minimizes subsequent processing requirements.

When magnetite contains significant amounts of wall rock or gangue minerals, a dry magnetic separator can be applied before grinding. This pre-selection step removes waste rock in advance, reduces grinding energy consumption, and enhances the purity of the final concentrate.

Technical Advantages and Applications

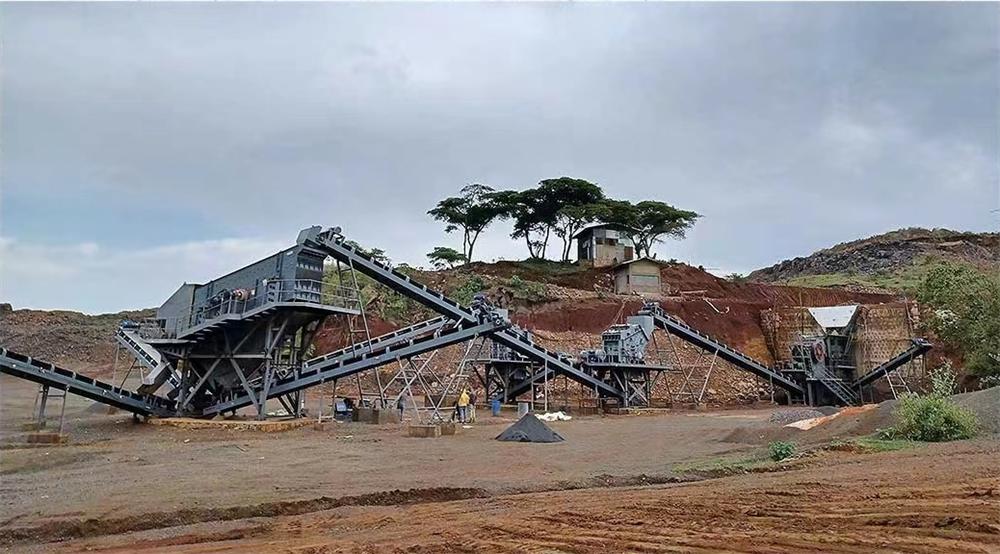

Modern magnetic separation technology has achieved significant improvements in efficiency, environmental protection, and automation

- High Recovery Rate: With proper configuration, both one-stage and two-stage separation deliver stable recovery of high-grade iron concentrates.

- Energy Saving & Eco-friendly: Phased magnetic separation reduces grinding energy consumption, while dry pre-selection lowers water usage, supporting sustainable mining.

- Intelligent Control: Many large-scale beneficiation plants now use automated monitoring systems for real-time adjustment and optimization, ensuring stable and efficient production.