Introduction of Lead-Zinc Ore Processin

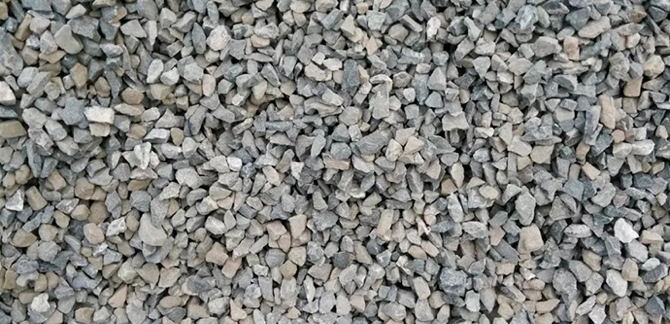

Lead-zinc ore is an important non-ferrous metal mineral widely used in various industrial sectors. To obtain high-grade lead and zinc concentrates, the ore must go through multiple stages such as crushing, grinding, and beneficiation. Among these, crushing plays a crucial role as it directly affects the efficiency of the entire production process. A well-designed crushing system can not only improve processing capacity but also ensure that the particle size meets the requirements for subsequent grinding and separation.

Common Crushing Equipment in Lead-Zinc Ore Plants

In lead-zinc ore processing, several types of crushers are commonly used depending on the hardness and characteristics of the raw material:

- Jaw Crusher: Mainly used for coarse crushing, it features large crushing ratio, strong capacity, and high reliability.

- Cone Crusher: Suitable for medium and fine crushing, especially effective for hard and abrasive ores, ensuring stable product particle size.

- Impact Crusher: Used in some cases to obtain better shape and uniform particle size in the crushed material.

- Vibrating Feeder & Screen: They ensure continuous feeding and accurate classification, forming an efficient crushing and screening system.

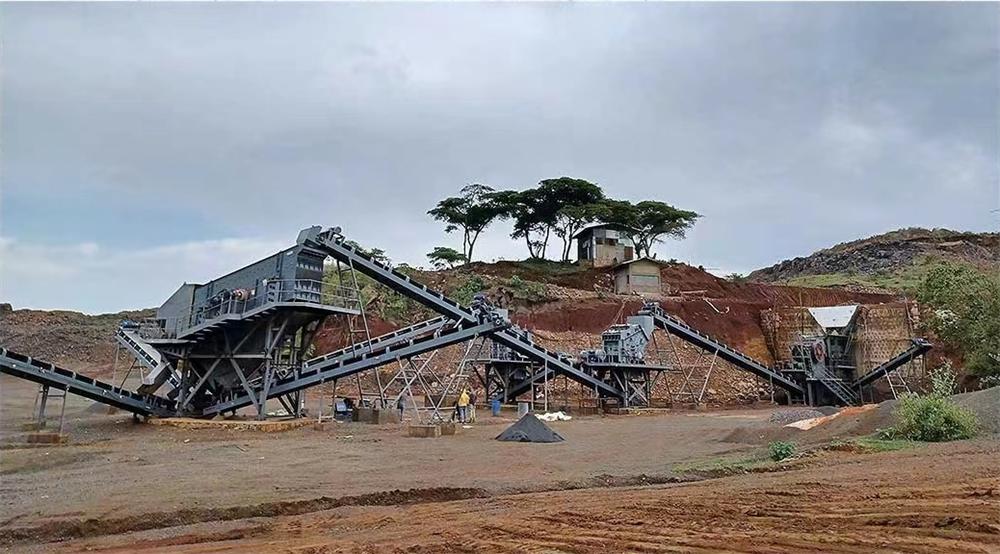

Crushing Line Design for Lead-Zinc Ore

A typical lead-zinc ore crushing line includes a vibrating feeder, jaw crusher, cone crusher, and vibrating screen. The raw material is evenly fed into the jaw crusher for primary crushing; the coarse material is then conveyed to the cone crusher for secondary crushing. After that, the finished products are screened and classified according to particle size.

Mining Alliance offers customized plant design according to customer requirements. Whether for small-scale mines or large beneficiation plants, our crushing lines are characterized by:

- Stable Performance — Ensuring long-term reliable operation;

- Easy Operation & Maintenance — Designed for user-friendly control and maintenance;

- High Efficiency & Energy Saving — Optimized structure to minimize power consumption;

- Beneficial for Later Processing — Produces uniform and well-graded materials ideal for grinding and flotation.

Application Advantages and Project Performance

Mining Alliance’s lead-zinc crushing lines have been successfully applied in multiple mining projects across Asia, Africa, and South America. Customers have reported that the equipment operates stably even under high load conditions and significantly improves the beneficiation recovery rate.

Our equipment adopts modular design and intelligent control systems, allowing flexible layout, easy transportation, and quick installation. These features make it especially suitable for modern mining enterprises pursuing high productivity and automation.