Overview of Copper Ore Processing

Copper is one of the most important non-ferrous metals, widely used in electrical equipment, construction materials, and industrial manufacturing. It is essential in power cables, transformers, thermal conductors, and precision instruments due to its excellent conductivity and corrosion resistance.

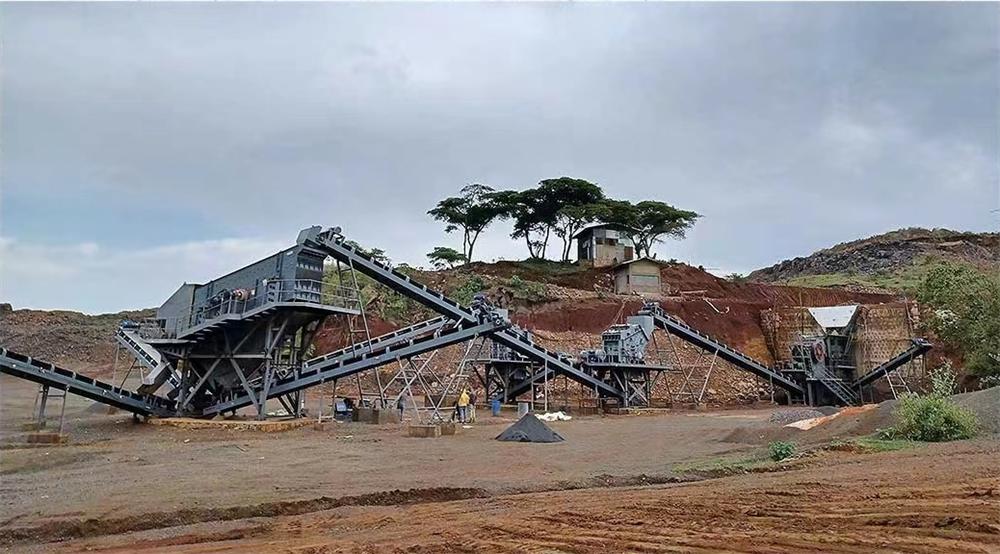

In the beneficiation process of copper ore, crushing is the very first and crucial stage. Before entering the grinding and flotation systems, raw copper ores must be reduced into uniform particle sizes. Efficient crushing equipment not only improves downstream grinding efficiency but also enhances the recovery rate of copper concentrate.

Copper Ore Crushing Process

The copper ore crushing process typically consists of three stages:

- Primary Crushing – Large copper ores are initially broken by a jaw crusher, ensuring coarse crushing efficiency and stable feeding for subsequent stages.

- Secondary Crushing – A cone crusher or impact crusher is used to further reduce particle size, achieving uniform granularity and improved liberation of minerals.

- Screening and Conveying – Crushed materials are classified by vibrating screens, with qualified materials entering the next processing step and oversized ones being re-crushed.

Some plants also utilize mobile crushing stations, which integrate feeding, crushing, and screening systems in one unit, offering flexibility and reduced infrastructure investment for remote mining areas.

Equipment Advantages in Copper Ore Crushing

Mining Alliance’s copper ore crushing systems feature advanced design and durable components, suitable for both stationary and mobile applications. The main advantages include:

- Stable Performance: Reinforced structure and wear-resistant materials ensure long-term operation under heavy loads.

- High Crushing Efficiency: Optimized chamber design improves throughput and uniform particle distribution.

- Easy Operation & Maintenance: Hydraulic systems simplify maintenance, while intelligent control ensures automatic adjustment.

- Energy Saving: Rational energy use minimizes consumption without compromising performance.

- Beneficial for Later Processing: Consistent product granularity enhances grinding efficiency and flotation recovery.

Mobile Crushing Station in Copper Ore Applications

With the advancement of mining automation, mobile crushing and screening stations have become increasingly popular in copper ore operations. These stations integrate multiple functions—feeding, crushing, screening, and conveying—into one compact system.

For example, in a 200TPH copper ore project in Southeast Asia, a Mining Alliance mobile crushing station achieved continuous operation with minimal downtime. The modular design allowed quick relocation between mining faces, while intelligent dust suppression systems ensured environmentally friendly operation.