Gabbro is a coarse-grained, dark-colored intrusive igneous rock mainly composed of plagioclase and augite. Known for its high hardness and durability, gabbro is one of the most commonly used raw materials in large-scale construction projects. It serves as a key source for crushed stone, concrete aggregate, decorative materials, and road base. As the demand for construction aggregates continues to grow, stationary crushing equipment has become the preferred solution for processing hard rock such as gabbro, thanks to its stability, efficiency, and capacity to handle large-scale production.

Stable Structure and High Production Capacity

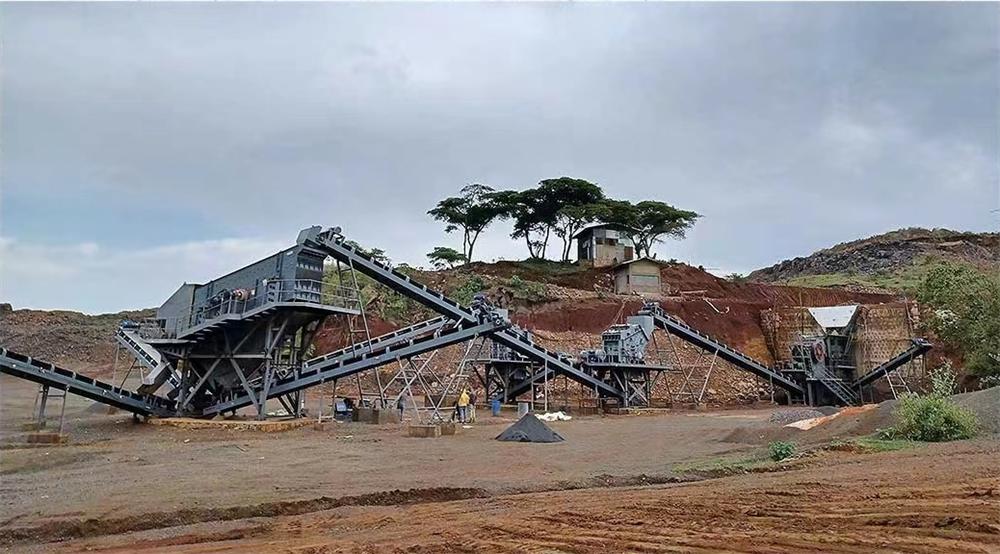

Stationary crushing equipment is built on a solid foundation, ensuring excellent operational stability during high-load crushing of hard materials like gabbro. The production line generally includes a vibrating feeder, jaw crusher, cone crusher, impact crusher, and vibrating screen. Each unit works in close coordination to form a continuous production process, providing high throughput and uniform particle size. Its powerful crushing force and optimized chamber design allow for efficient handling of hard rock while maintaining consistent product quality.

Suitable for Large-Scale Continuous Production

For mining and quarrying enterprises that require long-term, large-volume crushing operations, stationary crushing plants are ideal. Once installed, they can run continuously with minimal downtime. Their fixed layout allows integration with conveying systems, storage silos, and dust collection units, forming a complete and automated aggregate production system. This not only improves productivity but also ensures stable operation even under heavy-duty conditions.

Reliable Performance and Easy Maintenance

Stationary crushing equipment features a robust steel structure designed to resist vibration and impact from continuous feeding. Advanced lubrication systems, hydraulic adjustment mechanisms, and intelligent monitoring technologies ensure reliable operation and reduce maintenance frequency. Wear parts such as liners, blow bars, and hammers can be easily replaced, minimizing downtime and maintaining long-term performance stability.

Excellent Particle Quality for Construction Applications

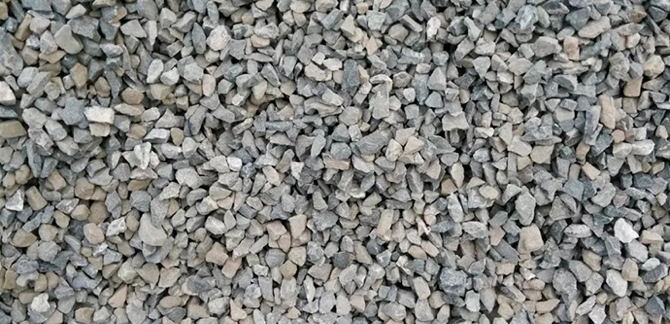

The aggregates produced from crushed gabbro by stationary crushing systems have a uniform shape, smooth surface, and high compressive strength. These features make them ideal for producing premium concrete, asphalt mixtures, and high-grade building materials. The high-quality aggregates help improve the durability, stability, and load-bearing performance of roads, bridges, and large-scale construction projects.

Energy Saving and Environmental Protection

Modern stationary crushing equipment adopts advanced energy-efficient motors, dust suppression systems, and noise reduction technologies. This helps reduce power consumption and dust pollution during gabbro crushing and screening, meeting the environmental requirements of modern green mining and construction industries. Through intelligent control, production parameters can be adjusted in real time to maximize efficiency and minimize energy waste.