Introduction to Marble and Its Industrial Significance

Marble is a type of recrystallized limestone formed under high temperature and pressure, which gives it a dense, durable structure and aesthetic appeal. Apart from being widely used in construction and decorative projects, the leftover material from marble processing also has high value. These by-products can be crushed into fine aggregates and powders, which are widely used in the chemical industry, fillers, and construction materials.

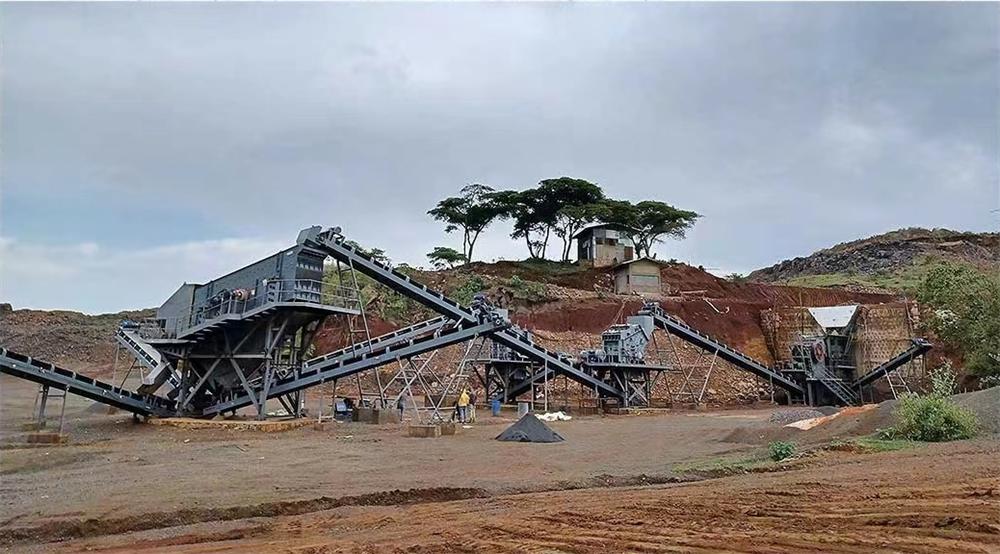

Advantages of Mobile Crushing Equipment for Marble

Mobile crushing equipment offers a flexible and efficient solution for marble processing. Unlike stationary crushing plants, mobile units can be transported to quarries or construction sites, reducing logistics costs and enabling on-site crushing.

Key Advantages:

- High Mobility: Entire mobile units can be moved on tracks or wheels, allowing immediate deployment on-site.

- Flexible Configuration: Can be equipped with jaw crushers, cone crushers, impact crushers, and vibrating screens to adapt to different marble types and output requirements.

- Quick Installation: Modular design allows rapid setup, minimizing downtime.

- Reduced Operational Costs: On-site crushing reduces transportation and handling costs while simplifying maintenance.

Typical Mobile Crushing Process for Marble

A standard mobile marble crushing plant involves several stages:

- Primary Crushing (Mobile Jaw Crusher): Large marble blocks are fed into the jaw crusher for coarse crushing.

- Secondary and Tertiary Crushing (Mobile Cone or Impact Crusher): The coarse material is further reduced to achieve desired sizes and improve aggregate shape.

- Screening and Conveying: Mobile vibrating screens separate crushed marble into various size fractions, while conveyors transfer finished products to storage or loading areas.

This system ensures consistent particle size, high-quality aggregates, and efficient production.

Features of Modern Mobile Crushing Equipment

Modern mobile crushing plants are designed for high efficiency and durability:

- Stable Performance: Heavy-duty construction ensures reliable operation even in harsh quarry environments.

- Energy Efficiency: Optimized hydraulic systems reduce power consumption while maintaining output.

- Environmental Protection: Dust suppression and noise control systems minimize environmental impact.

- Ease of Maintenance: Modular design, intelligent control, and automatic lubrication simplify maintenance and reduce downtime.

Applications and Case Studies

Mobile crushing equipment has been widely applied in marble quarries, construction projects, and chemical raw material production. For example, in India and Italy, mobile marble crushing plants are used to produce high-quality aggregates and fine powders for decorative tiles, cement additives, and industrial fillers. The mobility of the equipment allows operators to optimize production by relocating between quarries or project sites.