Introduction to Andesite and Its Industrial Uses

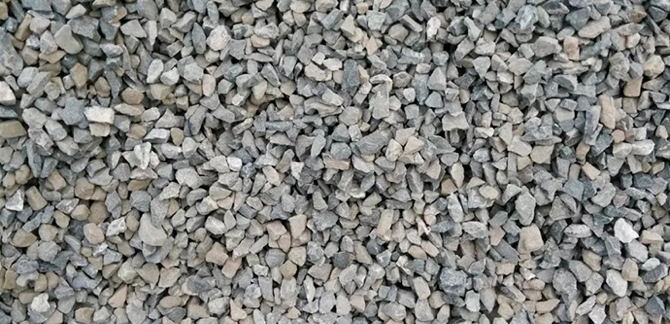

Andesite is a fine-grained volcanic rock with a mineral composition between granite and basalt. It is commonly found in volcanic areas formed by subduction zones, especially along continental-oceanic plate boundaries. Due to its high density, durability, and excellent mechanical strength, andesite is widely used in infrastructure projects such as road base materials, railway ballast, concrete aggregates, and building facades.

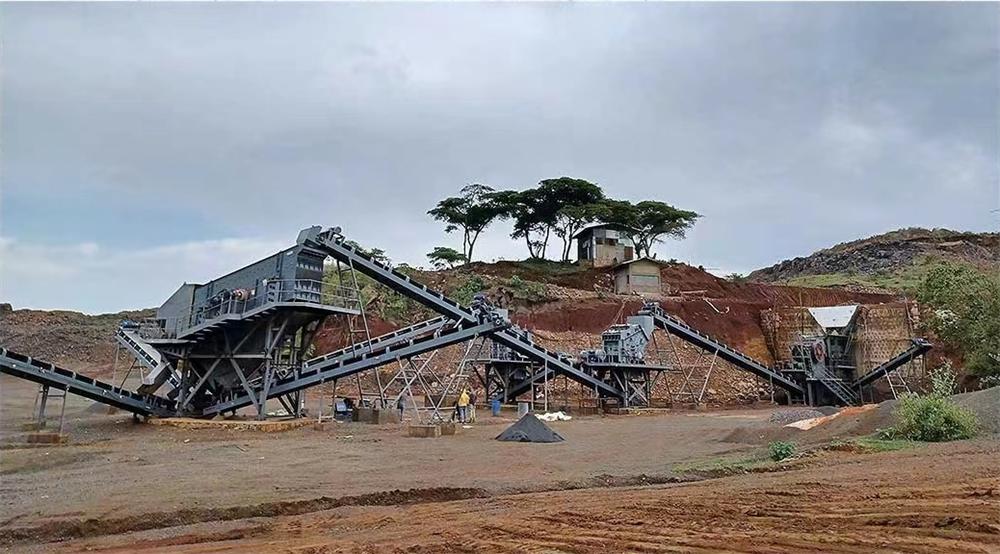

The Role of Fixed Crushing Equipment in Andesite Processing

In andesite production, fixed crushing equipment plays a crucial role in transforming large raw stones into uniform and high-quality aggregates. The processing line typically includes primary jaw crushers, secondary impact crushers or cone crushers, and screening systems.

- Primary Crushing (Jaw Crusher) – Large andesite blocks are fed into the jaw crusher for coarse crushing, reducing them to manageable sizes.

- Secondary Crushing (Cone or Impact Crusher) – The crushed materials are further processed into smaller and more uniform aggregates.

- Screening and Shaping – Vibrating screens and shaping machines classify and refine the particles to meet different construction specifications.

Compared with mobile units, fixed crushing plants offer higher stability, greater capacity, and lower operational cost—making them ideal for large-scale, long-term quarry operations.

Advantages of Andesite Crushing Plants Design

Modern andesite crushing plants adopt advanced automation systems, intelligent monitoring, and dust suppression technologies. These features ensure high efficiency, environmental protection, and easy maintenance.

- Stable Performance: Rigid steel structure and precision manufacturing guarantee reliable operation.

- Easy to Operate & Maintain: Centralized control systems simplify daily operation and maintenance.

- Good Aggregate Shape: The combination of impact and cone crushing ensures cubical aggregates ideal for high-grade concrete production.

- Energy Efficiency: Optimized design reduces power consumption and wear costs.

Typical Application Cases

Fixed andesite crushing equipment is widely used in highway and railway construction, hydropower projects, and urban infrastructure. For example, many large-scale quarries in Southeast Asia and South America adopt stationary plants for stable aggregate supply, ensuring continuous operation and consistent quality.