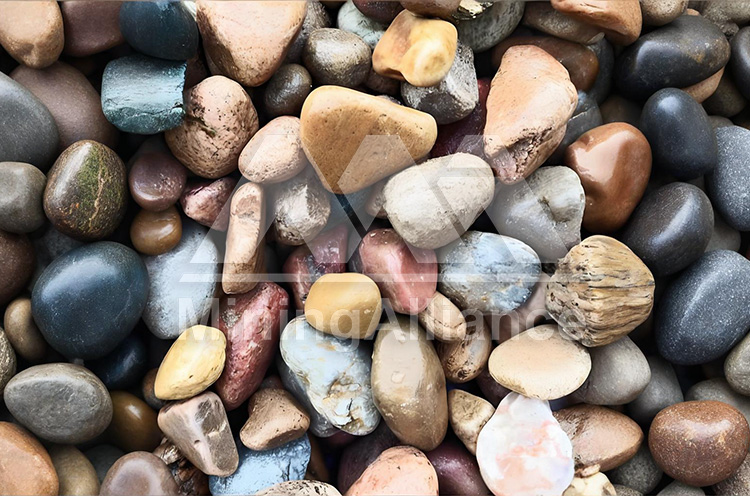

Introduction to River Stone

River stone is a type of natural stone, mainly originating from mountains that were ancient riverbeds lifted by geological movements millions of years ago. With increasing restrictions on natural sand extraction and the booming demand for infrastructure construction worldwide, manufactured sand has become a crucial resource. River stones serve as an excellent raw material for producing high-quality manufactured sand.

Advantages of Crushing Equipment for River Stone

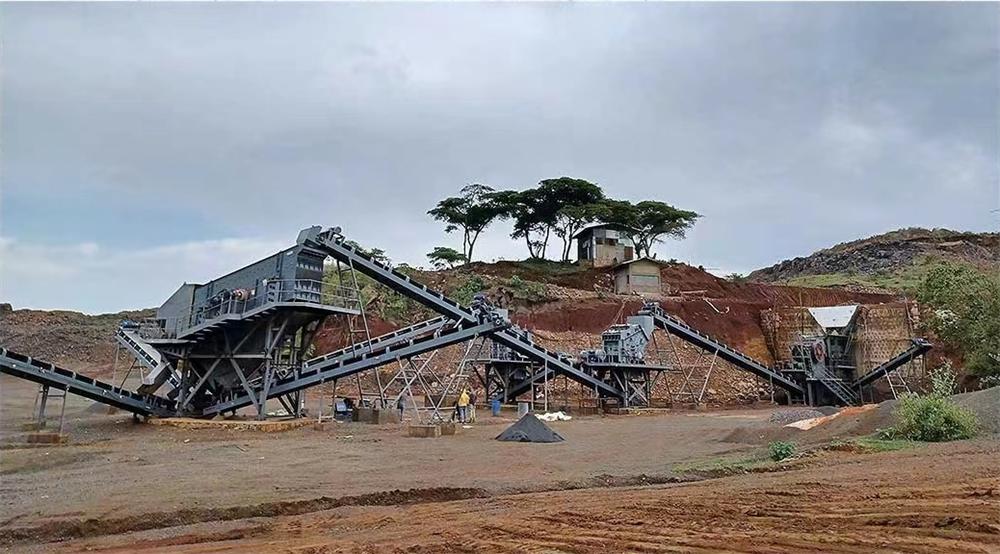

River stone crushing plants are designed to handle a wide range of stone sizes and produce aggregates suitable for various applications. Mobile and fixed crushing solutions both offer flexibility and efficiency for river stone processing.

Key Advantages:

- Stable Performance: Ensures consistent crushing quality even under continuous operation.

- Ease of Operation & Maintenance: User-friendly design and accessible components reduce downtime.

- Good Aggregate Shape: Produces well-shaped sand and gravel suitable for construction, concrete, and landscaping.

- Versatility: Capable of handling different stone sizes and producing various grades of aggregate.

Typical River Stone Crushing Process

A standard river stone crushing plant generally includes the following stages:

- Primary Crushing (Jaw Crusher): Breaks large river stones into smaller fragments.

- Secondary Crushing (Cone or Impact Crusher): Further reduces the size to meet the required specifications.

- Screening and Conveying: Vibrating screens separate aggregates by size, while conveyors transport finished products for stockpiling or direct use.

Applications in Industry

Crushed river stone is widely used in:

- Construction Industry: Road base, concrete, and building foundations.

- Infrastructure Projects: Bridges, dams, and urban development.

- Landscaping & Decorative Applications: Garden pathways, water features, and decorative gravel.