Introduction to Gravel and Its Uses

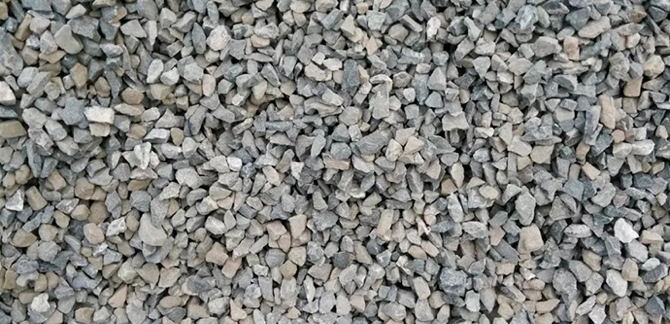

Gravel consists of small rocks and stones that are widely used as aggregates in concrete, road construction, and landscaping. It can serve as a structural base for roadways, assist in soil drainage, and also be used around planting beds for decoration or weed control. In some gravel pits, metals or minerals may also be present, making mining opportunities possible along with gravel extraction.

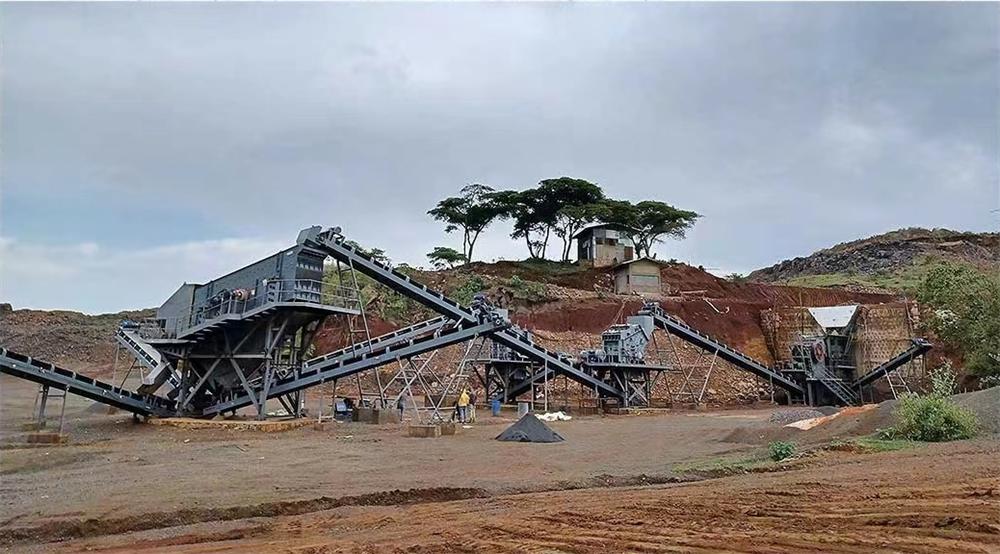

Advantages of Crushing Equipment for Gravel Production

Crushing equipment plays a crucial role in gravel production by transforming raw rocks into standardized aggregates suitable for industrial or construction use.

Key Advantages:

- Stable Performance: Heavy-duty crushers ensure reliable operation even under continuous production.

- Good Aggregate Shape: Advanced crushing technology produces well-shaped gravel suitable for concrete and road base applications.

- Ease of Operation & Maintenance: Modular designs and accessible components make the equipment user-friendly and reduce downtime.

Typical Gravel Crushing Process

A standard gravel crushing plant usually consists of:

- Primary Crushing (Jaw Crusher): Reduces large stones into smaller rocks.

- Secondary Crushing (Cone/Impact Crusher): Further reduces size for specific gravel gradations.

- Screening and Conveying: Vibrating screens sort material into different sizes, and conveyors transport the finished aggregates for storage or further processing.

Applications and Industries

Crushing equipment for gravel production is widely used in:

- Road and Highway Construction: Providing high-quality base and sub-base aggregates.

- Concrete Production: Producing aggregates for residential, commercial, and industrial concrete.

- Landscaping and Decorative Projects: Supplying gravel for gardens, walkways, and decorative features.

- Drainage Systems: Creating gravel layers for soil and water drainage systems.