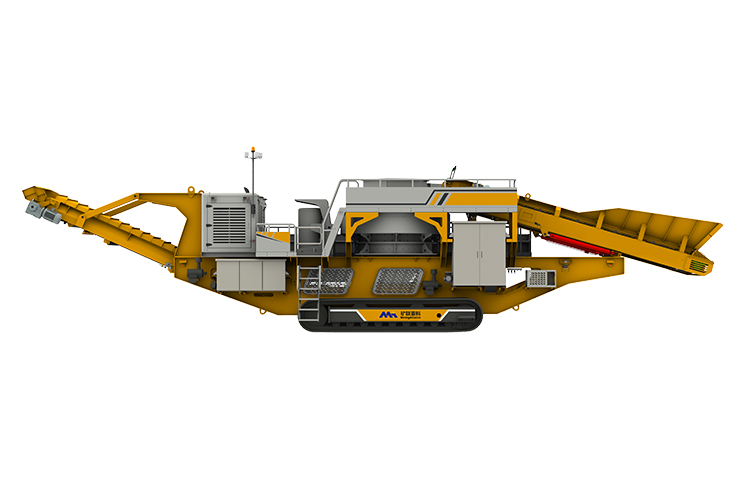

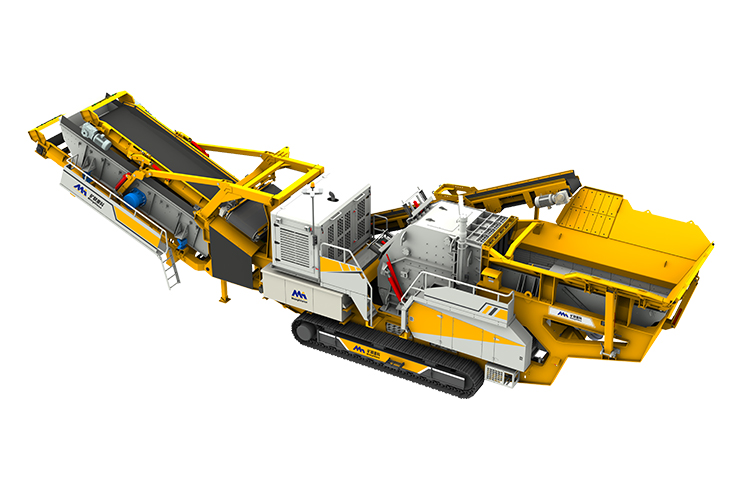

Marble processing projects often require a balance between production efficiency, flexibility, and product quality. The 200 TPH Mobile Marble Crushing Plant is designed to meet these demands by integrating core crushing and screening functions into a single mobile system, making it suitable for modern quarrying and aggregate production operations.

Practical Design for On-Site Marble Crushing

This mobile crushing plant is built to handle continuous marble processing with a nominal capacity of around 200 tons per hour. Its compact structure allows the plant to be positioned close to the raw material source, reducing the need for long-distance hauling and improving overall site logistics.

The plant layout supports smooth material flow from feeding to final screening, ensuring stable operation even during long working shifts.

Optimized Crushing Process

The production process typically starts with a mobile jaw crusher to break down large marble blocks into manageable sizes. Secondary crushing is carried out using an impact crusher or cone crusher, depending on the required final particle shape and grading.

Thanks to marble’s relatively consistent texture, the crushing system operates with steady load conditions, helping to maintain uniform output and minimize fluctuations in product quality.

Mobility for Changing Quarry Conditions

Quarry conditions often change as extraction progresses. The mobile design of this crushing plant allows operators to relocate the equipment easily as mining faces move. This flexibility helps maximize equipment utilization and reduces idle time caused by fixed plant limitations.

The plant can be transported by standard trailers and installed without heavy civil works, making it suitable for both permanent and temporary production sites.

Operational Stability and Maintenance

Wear-resistant components are selected based on marble’s physical properties, helping extend service intervals and reduce maintenance frequency. The control system allows operators to monitor key parameters such as feed rate, crusher load, and screen performance in real time.

Routine maintenance tasks are straightforward, supporting stable production and predictable operating costs.

Typical Applications

This mobile marble crushing solution is widely used for

- Quarry-based marble aggregate production

- Construction material supply

- Road base and infrastructure projects

- Recycling of marble waste materials