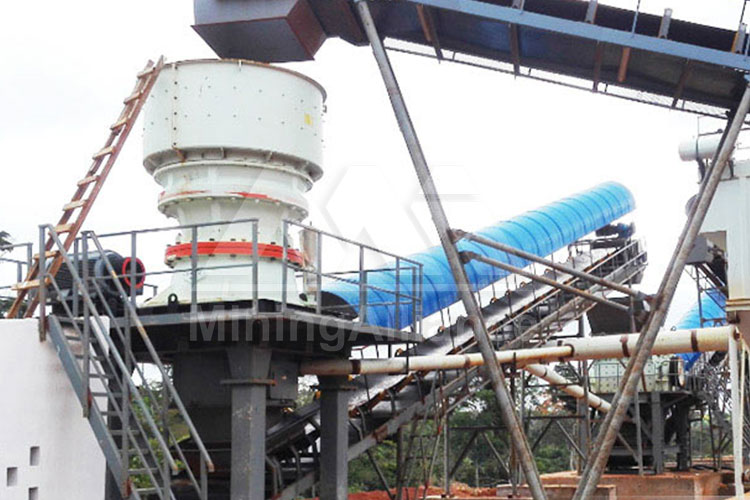

In modern mining, cone crushers have become indispensable core equipment due to their efficient crushing capabilities and versatility. This article explores their application scenarios and significant advantages in the mining sector, helping readers understand their importance in the industry.

Application Scenarios

Cone crushers are primarily used for secondary or tertiary crushing of medium-hard and harder materials, widely applied in mining, aggregate production, and metallurgical industries. They can break large ore pieces into smaller particles to meet the needs of subsequent processing or final product specifications. For example, in sand and gravel production lines, cone crushers are often used to process hard materials like granite and basalt, providing high-quality raw materials for the construction industry.

Technical Advantages

- Efficient Crushing Capability: Cone crushers employ laminated crushing technology, achieving a higher crushing ratio through the extrusion between the moving and fixed cones, significantly improving production efficiency.

- Versatility: The equipment can be equipped with different crushing chamber types according to needs, adapting to various operation modes such as coarse, medium, and fine crushing, offering a wide range of applications.

- Intelligence and Automation: Modern cone crushers integrate hydraulic adjustment and intelligent control systems, allowing real-time adjustment of the discharge opening and monitoring of operational status, ensuring equipment stability and safety.

Industry Trends

As the mining industry moves towards intelligence and environmental protection, cone crushers are also continuously innovating. New-generation equipment excels in energy saving, emission reduction, remote monitoring, and fault warning. For example, through optimized design and material selection, energy consumption is significantly reduced, while intelligent systems minimize the need for manual intervention. These improvements not only enhance production efficiency but also help enterprises achieve sustainable development goals.

Role in Environmental Protection and Sustainable Development

With the global emphasis on environmental protection and sustainable development, cone crushers are also evolving towards greener designs and applications. Modern equipment significantly reduces energy consumption and carbon emissions through optimized crushing chamber designs and high-efficiency motors. Additionally, equipped with dust removal and noise reduction devices, they effectively minimize dust and noise pollution during production, meeting environmental standards in the mining industry. Furthermore, cone crushers can process recycled aggregates, such as concrete blocks from construction waste, transforming them into reusable sand and gravel materials, promoting resource recycling. This feature not only brings economic benefits to enterprises but also contributes positively to environmental protection and sustainable development.

Integration in Automated Production Lines

In the context of intelligent manufacturing, cone crushers are increasingly integrated into automated production lines. Modern equipment supports remote monitoring and data analysis, allowing operators to view production data, equipment status, and fault warnings in real-time via mobile devices, greatly improving management efficiency. Additionally, cone crushers can seamlessly connect with upstream coarse crushing equipment and downstream screening equipment to form efficient automated production lines. For instance, in some large mining projects, cone crushers, linked with PLC control systems, achieve automatic adjustment of the discharge opening and intelligent distribution of material flow, ensuring the continuity and stability of the production line.

Enhancement of Mining Economic Benefits

The widespread application of cone crushers also directly contributes to the economic benefits of mining operations. Due to their efficient crushing capabilities and low maintenance costs, enterprises can process more materials within a unit time, significantly increasing output. Moreover, the durability and intelligent design of the equipment reduce downtime caused by failures, lowering operational costs. For example, in some medium-sized mines, the use of cone crushers has increased sand and gravel production efficiency by over 20%, creating substantial economic returns for enterprises.

Future Development Directions

Looking ahead, cone crushers still have immense potential for technological upgrades and application expansion. With the introduction of new materials and processes, the wear resistance and impact resistance of the equipment will be further enhanced, extending service life. Additionally, with the 5G technology and the Internet of Things, the remote control and data interconnection capabilities of the equipment will reach new heights. This means that future cone crushers will not only meet current mining needs but also perform in more complex conditions, bringing more possibilities to the industry.